Dr Paul Dunn, chair of the International Hologram Manufacturers Association (IHMA), highlights holography’s growing role in securing vehicle licence plates.

New developments in materials and advanced processes are driving growth in the use of holography, bringing innovation and interaction ever closer as the technology opens-up to new applications. Today, we are seeing holograms find their way into ever more sophisticated uses and this includes the automotive sector, where holographic designs and features are incorporated onto vehicle registration plates.

By the very nature of their application at the front and rear of every vehicle, registration plates are visible and exposed to everyone, including potential criminal activity. So, without effective security measures in place, these plates can be prone to manipulation and counterfeiting – often referred to as ‘cloning’.

Indeed, recent data in a report drawn up by Home Office officials, the National Police Chiefs’ Council and the Driver and Vehicle Licensing Agency (DVLA), suggests that there are about 13,000 cases of cloning being reported each year in England and Wales alone. Worldwide, incidents involving illicit licence plates continue to increase with resourceful criminals hiding their identities by using counterfeit, forged or stolen licence plates on their vehicles. The roll-out of Clean Air Zones (CAZ) is also driving the number of cloned vehicles now on roads, with drivers taking risky decisions to try and avoid punitive charges and fines.

However, governments are fighting back and implementing new initiatives to thwart these activities. In Australia for instance, the island state of Tasmania is leading the way in making vehicle identification more secure with what are described as ‘directional security marks’ that that cannot be removed physically or chemically embedded into automotive registration plates during the manufacturing process. The move makes it almost impossible for fraudulent plates to be made, according to the Government Minister for Infrastructure and Transport.

There are several reasons why people might want to make unauthorised reproduction or fake plates, but in general it’s for illicit purposes to avoid identification. The markings on the plates are designed to appear similar to the holographic authentication marks found on driving licences. Symbols are embedded in the retro-reflective sheeting used in making authentic number platers which makes the plate visible to a viewer standing about two metres back examining the rear plate.

However, the symbols then disappear when the viewer steps to one side or the other from the viewing position. The marks are also verifiable in diffuse daylight and by retro-reflected light at night, which is an important consideration for law enforcement agencies tasked with checking vehicle authentication in 24/7 road traffic operations.

The holographic marks are being applied to regular vehicle and trailer plates as well as government vehicle plates – the ministry is also currently exploring the logistics of applying them to custom and personalised plates.

The development reflects the increasing application of optics to protect licence plates – and vehicle owners and licencing authorities – from fraud. For example, Swiss company SICPA has developed a new approach to identifying vehicle plates, using liquid crystal technology directly applied to the plate substrate via a transfer foil.

Another leader in holograms on licence plates is OpSec, which sees vehicle identity as part of strategies to protect revenue and the safety of citizens and law enforcement. OpSec provides a wide range of optical security solutions for vehicle identification, which combine hologram technology with rugged durability and dependability.

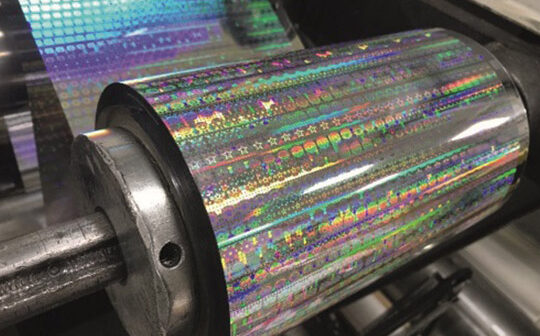

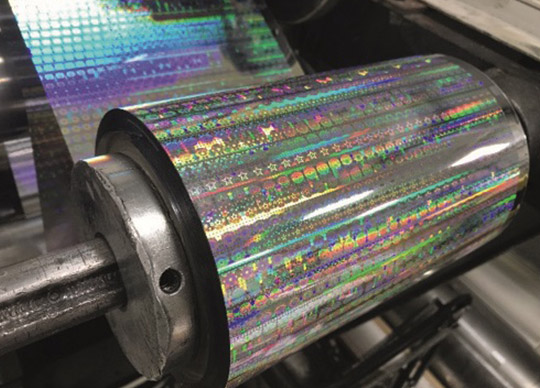

Registration plates, by nature of their application to the front and rear of vehicles, are visible and exposed to everyone including potential criminal activity. Without effective security measures in place, they are prone to manipulation and counterfeiting – often known as ‘cloning’. OpSec ChromEx is a secure hot-stamping foil solution intended for patch application to vehicle registration plates to help the fight against illegal activity. Designed to provide optimal adhesion to common retro-reflective substrates, the holographic foil delivers high durability and resistance to the effects of exterior environments.

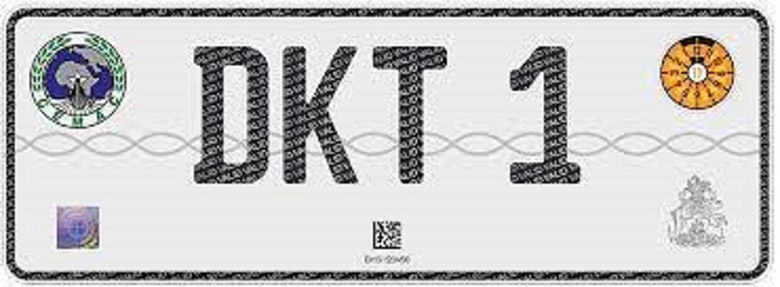

DKT, a German-based traffic security specialist, produces registration plates featuring holograms as an integral effect that can be individually designed and enhanced with a range of other security features: microtext, nano text and tilt effects. The individualised holograms are tamper-proof and are connected to the registration plate blank during production as part of a suite of anti-counterfeiting measures such as 2D barcodes with digital signature watermarks and laser marks, country features (logos, emblems, flags), stickers and individual hot embossing foils.

The capacity for holography to embrace and incorporate other data forms and recognition information continues to grow, creating exciting development in new areas. With continued advancements, there’s no reason why the technology will not continue to play a critical part at the leading-edge vehicle registration plates and other automotive-based ID solutions.